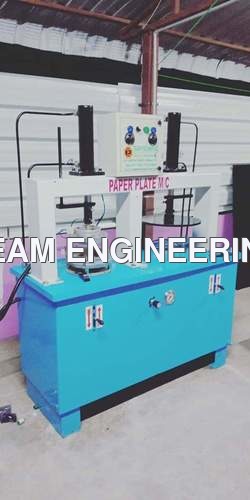

Paper Plate Making Machine

MOQ : 1 Piece

Paper Plate Making Machine Specification

- Grade

- Industrial Grade

- Type

- Automatic Paper Plate Making Machine

- Material

- Mild Steel

- Capacity

- 1200-4800 pieces/hr

- Computerized

- Yes

- Control System

- PLC Control

- Cutting Speed

- 60-80 pieces per minute

- Cutting Size

- 4 to 14 inches

- Cutting Thickness

- 80-500 GSM

- Voltage

- 220V/380V

- Power

- 2 kW

- Weight (kg)

- 500 kg

- Dimension (L*W*H)

- 1300 x 1200 x 1950 mm

- Color

- Blue/Grey

- Safety Features

- Emergency stop, safety covers

- Driven Type

- Electric

- Automation Grade

- Fully Automatic

- Noise Level

- Low

- Phase

- Single/Three Phase

- Production Rate

- 60-80 strokes/min

- Moulds Available

- Multiple moulds for different plate sizes

- Raw Material

- Paper, PE Coated Paper

- Installation

- On-site support available

- Paper Plate Size

- 4-14 Inch Adjustable

- Frequency

- 50/60 Hz

Paper Plate Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 10 Days

About Paper Plate Making Machine

With an increased proportion of technology, we are offering a qualitative assortment of Paper Plate Making Machine which saves time and cost. Used for making paper plates of different sizes which easily degrades, this machine is designed with the aid of cutting-edge technology in adherence to international quality standards. Our quality controllers inspect this range rigorously to ensure its performance. Besides, clients can avail this range at nominal price. Paper Plate Making Machine is featured with automatic counting, fast working speed & safe operation.

Details

Details

- Production: min.50-100 Kg/ 12 Hr

- Speed: 135~150

- Weight: 210Kg approx

- Require power: 2HP

- PLC base control panel

Efficient & Versatile Production

Designed for industrial use, this paper plate making machine operates at 60-80 strokes per minute and produces between 1,200 to 4,800 plates per hour. Easily switch between plate sizes with multiple included moulds, making it suitable for businesses with diverse product needs.

User-Friendly and Safe Operation

PLC-controlled and fully automated, the machine features an intuitive interface for operators. Built-in safety measures such as emergency stop and safety covers provide a secure working environment, ensuring smooth and accident-free operations.

Powerful Construction, Reliable Performance

Manufactured using durable mild steel and finished in industrial-grade blue or grey, this machine is engineered for longevity. With a capacity for thick paper (80-500 GSM) and a flexible voltage range (220V/380V), you can rely on this equipment for demanding production schedules.

FAQs of Paper Plate Making Machine:

Q: How does the fully automatic paper plate making machine operate?

A: The machine uses an electric drive and PLC control system, automatically feeding paper or PE-coated paper into heated moulds. It then forms and cuts the plates to the desired size with the press and cutting system, eliminating manual intervention and ensuring consistent production rates.Q: What plate sizes and shapes can be made with this machine?

A: You can produce paper plates ranging from 4 to 14 inches in diameter. The machine supports multiple, interchangeable moulds, offering flexibility for different plate shapes and sizes to cater to diverse customer requirements.Q: When is the machine suitable for use in production environments?

A: This machine is ideal for continuous, large-scale production, thanks to its ability to manufacture up to 4,800 pieces per hour. Its fully automatic and computerized system is well-suited for operations demanding high productivity and minimal downtime.Q: Where can the paper plate making machine be installed?

A: The machine can be installed in any suitable industrial facility in India. Whether the site uses a single or three-phase electric supply, on-site installation support by the manufacturer or supplier is available for seamless setup.Q: What is the process for making paper plates with this equipment?

A: The process involves loading suitable paper or PE-coated paper, selecting the desired mould, and starting the program. The machine then heats, presses, and cuts each plate automatically, delivering precise and uniform products at a speed of 60-80 pieces per minute.Q: What are the benefits of using a fully automatic PLC-controlled paper plate maker?

A: Automating with PLC control helps achieve higher output, consistent quality, and reduced labor costs. Enhanced safety features, fast production rates, and the flexibility to manufacture various plate sizes are added advantages for growing businesses.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paper Plate Making Machine Category

Hydraulic Double Die Paper Plate Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 V

Material : Mild Steel

Color : Blue & Silver

Hydraulic Paper Plate Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Voltage : 220V / 50Hz

Material : Mild Steel

Color : Blue and Silver

Paper Dona Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220V 240V AC

Material : Mild Steel

Color : Green/Blue (as per availability)

Disposal Paper Plate Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 220 V

Material : Mild Steel

Color : Blue / Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry