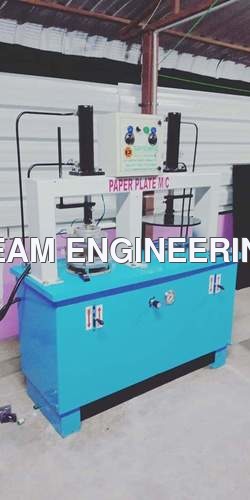

Automatic Paper Plate Making Machine

MOQ : 1 Piece

Automatic Paper Plate Making Machine Specification

- Grade

- Industrial Grade

- Type

- Automatic

- Material

- Mild Steel

- Capacity

- 10000-15000 pieces/10 hr

- Computerized

- Yes

- Control System

- PLC Control

- Cutting Speed

- 60-80 pieces/min

- Cutting Size

- 4 inch to 14 inch

- Cutting Thickness

- 80-500 gsm

- Voltage

- 220V

- Power

- 2 kW

- Weight (kg)

- 450 kg

- Dimension (L*W*H)

- 2000*900*2100 mm

- Color

- Blue-Grey

- Safety Features

- Emergency Stop Switch, Enclosure for Moving Parts

- Installation

- Onsite Provided

- Production Cycle Time

- 4-5 seconds/plate

- Max Plate Size

- 14 inch

- Frequency

- 50/60 Hz

- Automatic Grade

- Fully Automatic

- Noise Level

- Low

- Feeding Type

- Manual or Auto (Dual options)

- After Sale Service

- Available

- Operation Mode

- Automatic & Semi-Automatic

- Driven Type

- Electric

- Paper Type

- Single/Double PE Coated Paper, Aluminium Foil

- No. of Dies

- Double Die

Automatic Paper Plate Making Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Week

- Delivery Time

- 10 Days

- Main Domestic Market

- South India

About Automatic Paper Plate Making Machine

Reckoned as leaders in this industry, we are providing our esteemed clients with excellent quality Semi Automatic Paper Plate Making Machine for Food that needs two people to put the paper on both the working stations and obtain the final product. Ideal for making paper plates that are used in marriages, the offered machine is available in different specifications that fit the diverse requirements of the customers. This Semi Automatic Paper Plate Making Machine for Food is designed and manufactured with leading technology in order to meet the set industry norms. Besides, clients can avail the offered range at market leading prices.

Details

Details

- Operation: Hand lever, semi and fully automatic

- Production: 50,000 PCS /8 hour shift (approx)

- Type: Channel/closed frames

- Capacity: 150pcs/stroke

- Power: 7.5 hp

Advanced Dual-Mode Plate Production

This machine offers both automatic and semi-automatic operation modes, making it adaptable to different production needs. It supports manual or automatic feeding, giving users flexibility depending on workflow requirements. With its double die mechanism, high output is consistently maintained, while a range of materials including PE coated papers and aluminium foil are easily accommodated.

User-Centric Safety and Control

Operator safety and ease-of-use are priorities for this machine, featuring an emergency stop switch and secure enclosure for moving parts. The PLC-based control system allows precise programming and computerized operation, reducing downtime and ensuring smooth manufacturing cycles.

Comprehensive Support and Maintenance

Alongside sturdy construction and an industrial-grade build, this machine includes onsite installation and after-sale service. Manufacturers and suppliers across India benefit from dedicated customer support, ensuring optimal operation and minimal disruption to production.

FAQs of Automatic Paper Plate Making Machine:

Q: How does the Automatic Paper Plate Making Machine ensure consistent plate quality?

A: The machine uses a computerized PLC control system and double die design to maintain uniformity during production. Consistent feeding, adjustable cutting speed, and precise thickness control (from 80 to 500 gsm) help deliver quality plates every cycle.Q: What is the process for switching between semi-automatic and automatic operation modes?

A: Operators can switch between modes using the machines control panel. In semi-automatic mode, manual feeding is possible; switching to automatic enables uninterrupted feeding, allowing for higher throughput when needed.Q: When is onsite installation available for this machine?

A: Onsite installation is provided upon delivery across India, ensuring the equipment is correctly set up and running efficiently from day one. After-sale service is also available for ongoing support.Q: Where can this machine be installed and used effectively?

A: Due to its robust dimensions (2000 x 900 x 2100 mm) and 450 kg weight, it is best suited for industrial manufacturing setups or commercial production units specializing in disposable products.Q: What safety features are integrated into this paper plate making machine?

A: The equipment includes an emergency stop switch and enclosures for moving parts, minimizing operator risk and ensuring compliance with industrial safety standards.Q: How does the dual feeding (manual/auto) option benefit production?

A: The dual feeding system gives operators the choice of manual intervention for smaller runs or automatic feeding for large batches, enhancing flexibility and minimizing production downtime.Q: What types of plates and materials can this machine handle?

A: It can handle plate sizes ranging from 4 inches to 14 inches and materials such as single/double PE coated paper and aluminum foil, allowing for a wide variety of disposable plate products.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Paper Plate Making Machine Category

Hydraulic Double Die Paper Plate Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Grade : SemiAutomatic

Cutting Size : 414 Inch

Paper Plate Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Grade : Other, Industrial Grade

Cutting Size : 4 to 14 inches

Multi Paper Plate Making Machine

Price Range 104000.00 - 265000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Grade : Other, Industrial Grade

Cutting Size : 414 inches

Fully Automatic Paper Plate Machine

Price 70000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Mild Steel

Grade : Industrial Grade, Other

Cutting Size : 4 inches 12 inches

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry